MEP coordination? Oh, we figured that out on site.

Famous last words of countless site engineers before a concrete slab had to be hacked open to reroute a duct. If you’ve ever watched an architect, a plumber, and an HVAC guy argue over who owns the 300mm space above the ceiling, you know MEP clashes are not just technical issues — they’re relationship destroyers.

From ducts that defy gravity to drainpipes that mysteriously end behind beams, MEP coordination (or the lack of it) is the ghost haunting modern construction sites. And if you’re thinking, “This won’t happen to us,” trust me — your site plumber and electrician are already measuring the same shaft for two different uses.

Understanding the Root Cause: Why Do MEP Clashes Happen?

Let’s get serious for a moment. MEP (Mechanical, Electrical, and Plumbing) clashes occur when two or more building services physically interfere with each other or with structural components. These clashes aren’t just about design mismatches — they’re the result of:

- Late involvement of MEP consultants in the design stage

- Poor inter-disciplinary communication between architects, civil engineers, and MEP teams

- Lack of coordination tools, like BIM or clash detection software

- Unclear shaft allocation and vertical zoning

- Site improvisation due to missing drawings or unrealistic designs

These issues result in delays, cost escalations, design compromises, and post-handover maintenance nightmares.

The 5 Most Common Types of MEP Clashes

- Duct vs. Beam Conflicts

Ducts planned too large or too low end up clashing with structural beams. Result: the duct is resized, bent, or removed altogether. - Drainage Pipe vs. Electrical Conduit

Especially in slab zones where plumbers and electricians often route without checking each other’s drawings. - Fire Sprinkler vs. False Ceiling Design

Heads poke out at odd locations, or drop too low because the ceiling height wasn’t finalized. - HVAC Indoor Unit vs. Wall-Mounted Switchboards

A common issue in corridor or commercial layouts where wall-mounted MEP systems aren’t coordinated. - Shaft Overload

Everyone thinks they’ll “manage” in the shaft, till it’s bursting with drains, cables, and chilled water pipes all jammed together.

How to Prevent MEP Clashes: A Step-by-Step Approach

Here’s a Mind Map of Preventive Action:

[MEP Clash Prevention]

|

———————————————

| | |

[Design Phase] [Tools] [Execution Stage]

| | |

– Early MEP input – Use BIM – Pre-start site meetings

– Define shaft size – Clash detection – Service layout markings

– Freeze ceiling ht – Shared 3D model – Red-flag walk-throughs

A. Bring MEP In Early

Architectural design should not precede MEP zoning. Bring MEP consultants in during conceptual planning, not after the walls are drawn.

B. Zone Your Building

Set rules: electrical runs on the left, drainage right; HVAC in designated bands. Plan for vertical and horizontal service zoning.

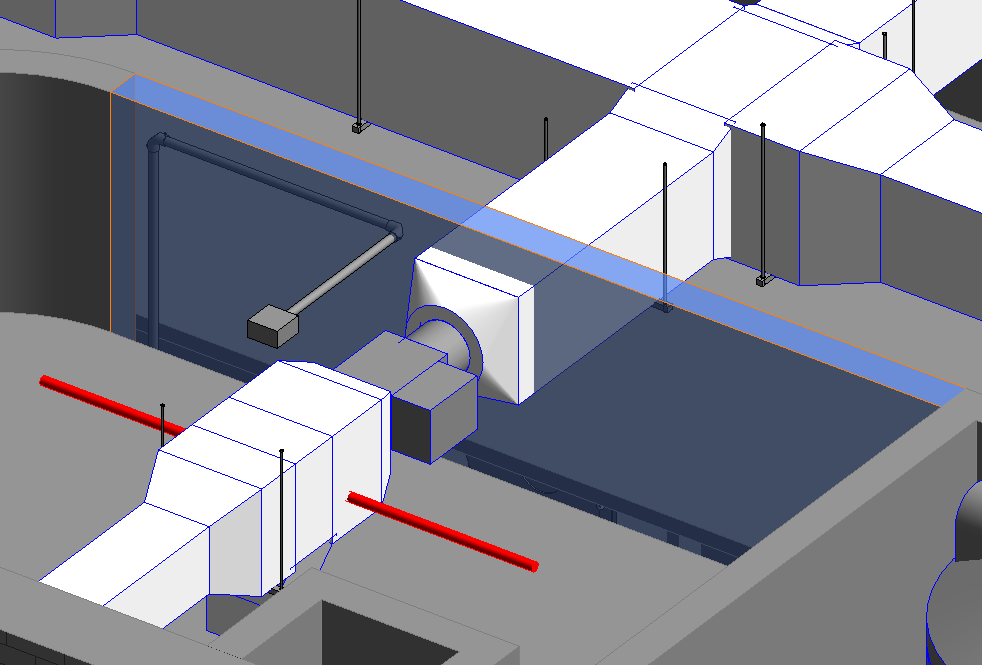

C. Adopt BIM or 3D Coordination

Yes, even for small to mid-size projects. Tools like Revit, Navisworks, or Trimble can catch clashes before they reach the site.

D. Conduct Clash Reviews

Run clash detection reports, not just pretty 3D models. Review them with all disciplines together in joint coordination meetings.

E. Use Shared Service Drawings on Site

One set of drawings that shows all services together. It’s the difference between “installing in harmony” and “guessing who goes first.”

F. Field Verification + Marking

Before closing a slab or false ceiling, walk the site with the drawings, verify routings, and mark critical points.

Pro Tip: Allocate “Collision Zones”

Mark zones like toilet shafts, basement ceilings, or corridor ducts as “high clash” areas. Review these in extra detail during design and before execution.

A Note for Builders & Architects

You spend months perfecting a façade, but allow service pipes to be rerouted on site? That’s like designing a luxury hotel and forgetting the plumbing. MEP doesn’t have to be a mystery. It just needs structure, coordination, and early attention.

Conclusion

You can build faster, cleaner, and smarter — or you can keep hiring guys with jackhammers and patch-up plaster. The choice is yours.

Don’t let MEP be the villain of your project story. Make it your secret strength.

Clashes often occur because MEP consultants are brought in too late, or architectural and structural designs are finalized without considering service coordination. Without early collaboration and shared planning, overlaps become inevitable.

Yes. While often assumed to be for large-scale projects, BIM can greatly reduce clashes even in smaller developments. It helps visualize and coordinate all services in 3D before they reach the site, preventing expensive rework.

Proper shaft sizing and assignment during the design phase ensure that each service has its designated path. Without this, multiple teams may try to use the same shaft space, leading to congestion and execution issues.

This requires pre-start site meetings, ground markings, and joint walkthroughs with all service teams. Drawings should be updated, printed, and verified at regular intervals to reflect the actual approved routing.

Toilet shafts, basement ceilings, corridor service ducts, and false ceiling areas are the most common zones. These areas have limited space but high service density, making coordination critical.

Technology helps significantly, but physical site checks, team communication, and hands-on verification remain essential. On-site clarity, especially before slab casting or ceiling closures, is key to preventing conflicts.