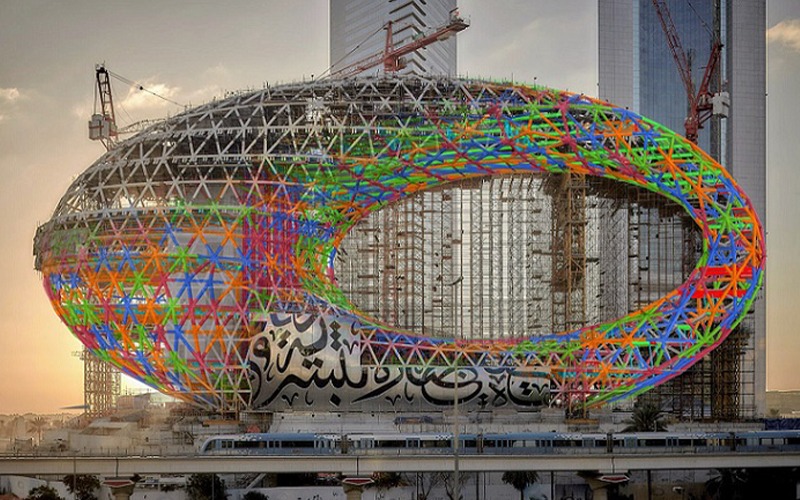

Blueprints are getting bolder, buildings are getting smarter — and MEP is right at the center of it all.In 2025, Mechanical, Electrical, and Plumbing systems are no longer the quiet backstage crew. They’re calling the shots on energy performance, water conservation, build speed, and long-term building health.

From luxury high-rises to industrial townships, how you plan your MEP will define how your project performs — not just at handover, but for years down the line.

Quick Summary: What’s Changing in MEP This Year?

If you’re in construction, here’s what you need to keep on your radar in 2025:

- Power is going local – On-site solar, microgrids, and backup storage are becoming essential.

- Buildings are getting brains – IoT-powered systems are automating comfort, safety, and efficiency.

- Water waste won’t cut it – Conservation systems and smarter plumbing are the new norm.

- Everything’s going electric – Clean, efficient electrification is replacing gas and diesel systems.

- Prefab is the new normal – Modular MEP installations are speeding up timelines across sectors.

- Decentralized Energy Systems and Microgrids

With grid dependency becoming riskier and renewable energy more affordable, buildings are now generating and managing their own power.

From solar rooftops and hybrid inverters to lithium battery storage and load-sharing across microgrids — the push toward decentralized energy is becoming mainstream.

Why it matters: MEP teams must now account for energy flow from multiple sources, grid interaction, and backup autonomy — all while keeping power quality stable.

- Smart MEP with IoT Integration

In 2025, your building’s systems can talk — to each other and to you.

IoT sensors and automation platforms are transforming HVAC, lighting, and water systems from passive utilities into responsive, intelligent networks.

Use cases include:

- Lighting that adapts to occupancy and natural daylight

- HVAC systems that optimize based on room usage and external climate

- Plumbing that alerts and auto-isolates when a leak is detected

On the jobsite: It leads to fewer service calls, improved tenant comfort, and long-term efficiency — without increasing operational complexity.

- Water Conservation and Zero-Waste Plumbing Systems

Water is under pressure — literally and politically. And MEP consultants are rising to the challenge.

Builders are integrating:

- Greywater reuse systems

- Non-electric overflow control valves (like Tankmate)

- Leak-proof plumbing layouts

- Flow restrictors, smart meters, and dual-pipe setups

Payoff for developers: Fewer water-related complaints, lower operating costs, and a clear advantage in green building certification and compliance.

- Electrification of Building Systems

As gas bans and emission targets get stricter, buildings are transitioning to fully electric MEP systems that align with decarbonization goals.

What’s showing up on design boards now:

- Heat pumps replacing traditional HVAC and water heating

- Electric kitchens with induction cooktops

- EV charging baked into the load schedule

- Battery backup instead of diesel gensets

Design shift: Panels are getting smarter and heavier, and load planning is becoming central to every MEP conversation.

- Prefabrication and Modular MEP Installations

Faster builds. Cleaner execution. Lower error rates.

That’s what prefabricated MEP assemblies are bringing to the table in 2025. From riser shafts and plumbing walls to prewired electrical panels and plug-in HVAC kits — more of your MEP is now being built in factories instead of congested sites.

Who’s leading the shift: Developers in healthcare, hospitality, and high-density housing looking to save weeks off their timelines — without compromising on quality.

Final Thoughts

MEP isn’t just about making buildings function — it’s about making them efficient, intelligent, and future-proof.

In 2025, these five trends are defining how buildings perform long after ribbon-cutting. The earlier they’re integrated into project planning, the more value they deliver — in savings, in uptime, and in sustainability.

FAQs

Low-voltage systems improve safety, reduce fire risk, and make it easier to integrate solar and battery systems. They're also more flexible for modern electrical layouts like USB-C grids and modular workspaces.

Pumps, pipes, and ducts can transmit unwanted noise through slabs and walls. Proper MEP-acoustic coordination reduces complaints and enhances comfort — especially in residential and mixed-use buildings.

Partial redundancies like dual water feeds or zoned electrical circuits help prevent total system failure. It’s a cost-effective way to boost reliability without duplicating entire systems.

Yes. AR-based layout previews and QR-tagged conduits are already helping reduce clashes during execution, improve routing accuracy, and minimize slab hacking or delays.

It means MEP systems are laid out in a way that allows for easy inspection and maintenance — using service corridors, removable panels, and zone-based controls that reduce the need for invasive repairs.

Catching conflicts early — before civil and finishing work begins — drastically reduces rework, cost overruns, and project delays. It also improves build quality and handover readiness.